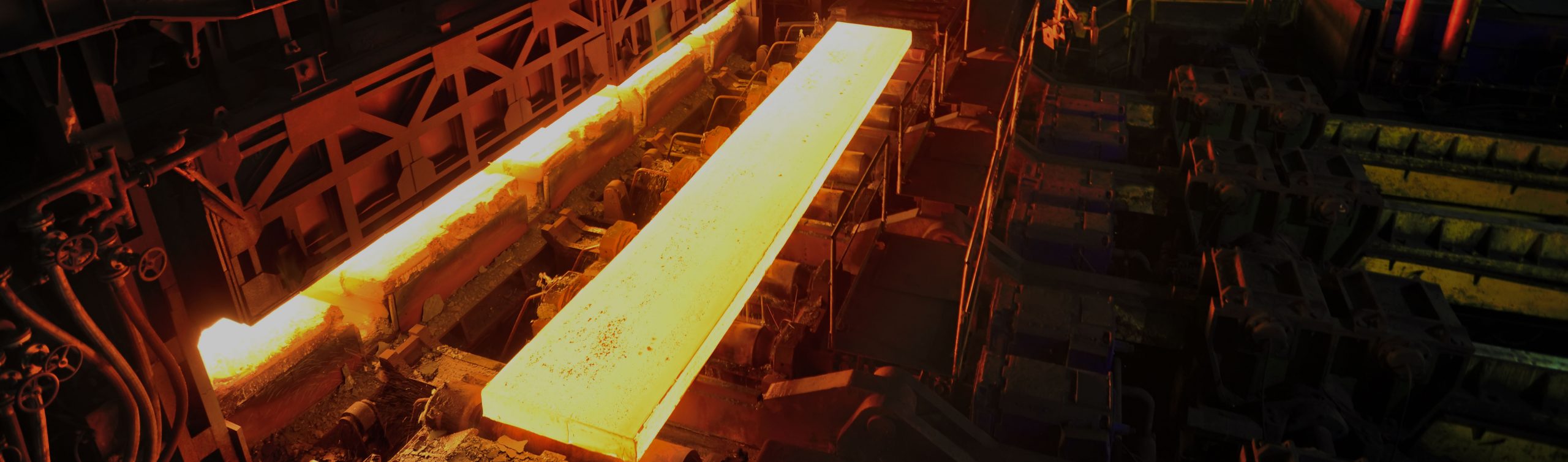

heating up natural or synthetic organic materials

Especially in the food industry, but also when processing plastics, paper, painted metal or glass, heat is often an essential part of a production process. But heating up natural or synthetic organic materials can produce and release a number of particularly harmful vapours such as acrolein or furans. You won’t find these chemicals in the safety data sheets because they are only formed during the heat treatment and are not yet present in the raw materials themselves. As a result, they are sometimes overlooked by health and safety advisors. However, these highly toxic fumes, which spread very easily, are often the main respiratory risk in a production hall. They include a wide range of reactive or aromatic substances that have been shown to be carcinogenic or to cause irreversible damage to the human body.

Because these vapours are so harmful, they have extremely low legal exposure limits, often just a few micrograms per cubic metre of air, which can quickly be exceeded. It is therefore important to make sure that these substances are not released at all during a heat treatment. The first step is a foolproof extraction during the heat process itself, but even afterwards when opening the oven or during the cooling of the products, you don’t want contamination of the workplace with toxic residual vapours.

Especially in the food industry, but also when processing plastics, paper, painted metal or glass, heat is often an essential part of a production process. But heating up natural or synthetic organic materials can produce and release a number of particularly harmful vapours such as acrolein or furans. You won’t find these chemicals in the safety data sheets because they are only formed during the heat treatment and are not yet present in the raw materials themselves. As a result, they are sometimes overlooked by health and safety advisors. However, these highly toxic fumes, which spread very easily, are often the main respiratory risk in a production hall. They include a wide range of reactive or aromatic substances that have been shown to be carcinogenic or to cause irreversible damage to the human body.

Because these vapours are so harmful, they have extremely low legal exposure limits, often just a few micrograms per cubic metre of air, which can quickly be exceeded. It is therefore important to make sure that these substances are not released at all during a heat treatment. The first step is a foolproof extraction during the heat process itself, but even afterwards when opening the oven or during the cooling of the products, you don’t want contamination of the workplace with toxic residual vapours.

DIY exposure measurements - a cheap and quick solution!

You want to ensure everything is ok by measuring for all gases with sufficient sensitivity so that you can make timely and efficient adjustments. The new DIY measurement from Atmosafe gives you that clarity: a single measurement that you can schedule and perform yourself, giving you an immediate and complete picture of the volatile substances present and the risk they pose.

Want to learn more about our DIY exposure measurements?

Click here!

You want to ensure everything is ok by measuring for all gases with sufficient sensitivity so that you can make timely and efficient adjustments. The new DIY measurement from Atmosafe gives you that clarity: a single measurement that you can schedule and perform yourself, giving you an immediate and complete picture of the volatile substances present and the risk they pose.

Want to learn more about our DIY exposure measurements?

Click here!